Bayanin Meta: Bincika dabarun gyare-gyaren allura na ci gaba don ƙirar fitilun mota. Koyi game da zaɓin abu, ƙirar ƙira, da ɗorewa a cikin kera fitilun mota.

Gabatarwa

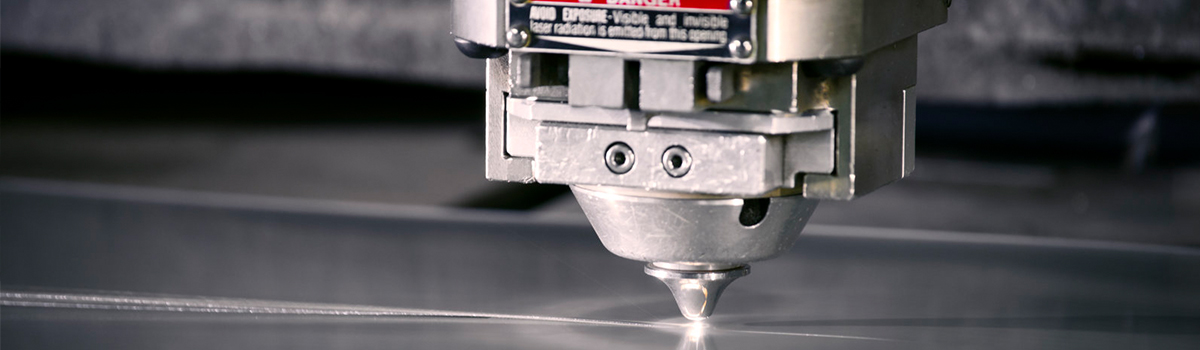

Masana'antar hasken wuta ta mota tana buƙatar madaidaicin madaidaicin, tare da gyare-gyaren fitilolin mota waɗanda ke buƙatar matakan haƙuri a ƙarƙashin 0.02mm. Yayin da ƙirar abin hawa ke tasowa zuwa ga slimmer LED arrays da katako mai daidaitawa, injiniyoyin ƙirar allura suna fuskantar ƙalubalen da ba a taɓa gani ba. Wannan jagorar ta rushe matakai masu mahimmanci da dabarun yanke hukunci masu mamaye filin.

1. Zaɓin Abu: Daidaita Kayan gani & Dorewa

Mahimman kalmomi: Polycarbonate allura gyare-gyare don fitilolin mota, ma'aunin thermoplastics na mota *

- PC (Polycarbonate): 90% na fitilolin mota na zamani suna amfani da PC don watsa haske 89% da juriya na zafi 140°C.

- Lenses PMMA: ruwan tabarau na biyu galibi suna haɗa PMMA don juriya.

- Abubuwan Additives: 0.3-0.5% UV stabilizers hana yellowing; ma'aikatan anti-hazo suna rage kumburin ciki.

Pro Tukwici: BASF's Lexan SLX da Covestro's Makrolon AL suna ba da ingantaccen kwarara don hadadden bututun haske.

2. Ƙirar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwar Ƙwararrun Ƙwararrun Ƙwararrun Ƙwararrun Ƙwararrun Ƙwararru

Maƙasudin Maƙasudi: ƙirar bangon bangon bakin ciki, ƙirar fitilar fitilar mota *

- Kaurin bango: 1.2-2.5mm bango yana buƙatar allura mai sauri (800-1,200 mm / s) don hana alamun jinkiri.

- Cooling Conformal: Tashoshin alloy na jan karfe da aka buga na 3D suna haɓaka ingancin sanyaya ta hanyar 40%, rage lokutan sake zagayowar.

- Yana gamawa: VDI 18-21 (mai rubutu) don masu rarrabawa vs. SPI A1 ( madubi) don bayyanannun ruwan tabarau.

Nazarin Case: Tesla Model 3 matrix LED module ya sami shafi na 0.005mm ta amfani da sarrafa zafin jiki na gradient.

3. Ma'auni na Tsari: Haɓaka Bayanan Bayanai

Mahimman kalmomi: sigogin gyaran allura don fitilun mota, ingantaccen ƙirar fitilar mota *

| Siga | Yawan Rage | Tasiri |

|——————–|————————-|—————————-|

| Narke Temp | 280-320C (PC) | Bayyanar gani |

| Ciwon allura | 1,800-2,200 bar | Cika ƙananan siffofi |

| Lokacin Shiryawa | 8-12 seconds | Yana hana alamar nutsewa |

Haɗin IoT: Na'urori masu auna firikwensin matsa lamba na lokaci-lokaci suna daidaita danko yayin cikawa (Masu yarda da masana'antu 4.0).

4. Dorewar Halin Gyaran Masana'antu

Maƙasudin Maƙasudi: gyare-gyaren fitilun fitillu masu dacewa, kayan da aka sake fa'ida a cikin hasken mota*

- Sake amfani da sinadarai: Fasahar sabunta PC ta Eastman tana ba da damar sake sarrafa abun ciki 50% ba tare da rawaya ba.

- Mold Coatings: CrN / AlCrN PVD shafi yana tsawaita rayuwar mold da 300%, rage sharar karfe.

- Adana Makamashi: Duk-matsalolin wutar lantarki sun yanke amfani da makamashi da kashi 60% vs tsarin hydraulic.

Bayanan kula: EU 2025 Umarnin ELV ya ba da umarni 95% sake yin amfani da hasken gaba.

5. Bunƙasa Fasaha don Kallon

Mahimman kalmomi: AI a cikin ƙirar ƙira, 3D bugu na ƙirar mota *

- AI Simulation: Autodesk Moldflow 2024 yana annabta layin weld tare da daidaito 92%.

- Kayan Aikin Haɓaka: Abubuwan da aka sanya masu tauri (HRC 54-56) haɗe tare da sanyaya bugu na 3D.

- Smart Molds: Abubuwan da aka haɗa RFID suna waƙa da tarihin kulawa da sawa alamu.

Kammalawa

Ƙwararrun gyare-gyaren fitilun mota na buƙatar haɗakar kimiyyar abu, aikin injiniya daidai, da ƙirƙira na dijital. Kamar yadda motoci masu cin gashin kansu ke fitar da buƙatun tsarin hasken lantarki mafi wayo, ɗaukar waɗannan dabarun ci gaba zai sanya masana'antun su kasance kan gaba a masana'antar.

Kira zuwa Aiki: Kuna buƙatar bincike mai gudana don aikin hasken gaban ku na gaba? [ Tuntuɓi ƙwararrunmu] don shawarwarin fasaha kyauta.

Lokacin aikawa: Afrilu-01-2025